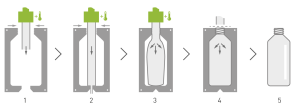

Extrusion blow production

Plastxs has in house production capabilities to produce extrusion blow moulding products ranging from 10ml up to 3ltr.

Extrusion blow moulding, also known as blow moulding, is a plastics processing method for the production of hollow bodies made of thermoplastics. The melted polymer is pressed through the nozzle via a screw conveyor, resulting in a tubular preform.

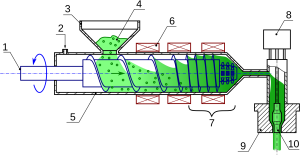

Injection Moulding production

Plastxs has injection moulding capabilities for small and medium sized components like closures, tubes and plastic devices.

Injection moulding is a primary shaping process that is mainly used in plastics processing. The respective material is liquefied with an injection moulding machine and injected under pressure into a mould, the injection mould.

High precision and high level of detail: The cast aluminum mould enables the production of finished parts in complex shapes weighing from a few grams to several kilograms. Injection moulding rarely requires post-manufacture machining.

Roll on production

Plastxs has it’s own production for injection moulding the roll on components in various dimension as well as assembly lines to assemble the injection moulding component with a stainless steel metal ball, glass ball or plastic ball. The assembly line is equipped with in line inspection.

A roll on is a combination product of an injection moulded part with an inserted ball made of stainless metal, glass or plastic.

Trading goods like: